Other products

Automating the world, one use case at a time.

Use cases

We automate what others can’t, making robotic handling of easily deformable materials accessible for everybody. There are unlimited potential use-cases.

Sewing

Returns handling

Assembly of rubber parts

Cable harnesses

Food picking & processing

Automating automation

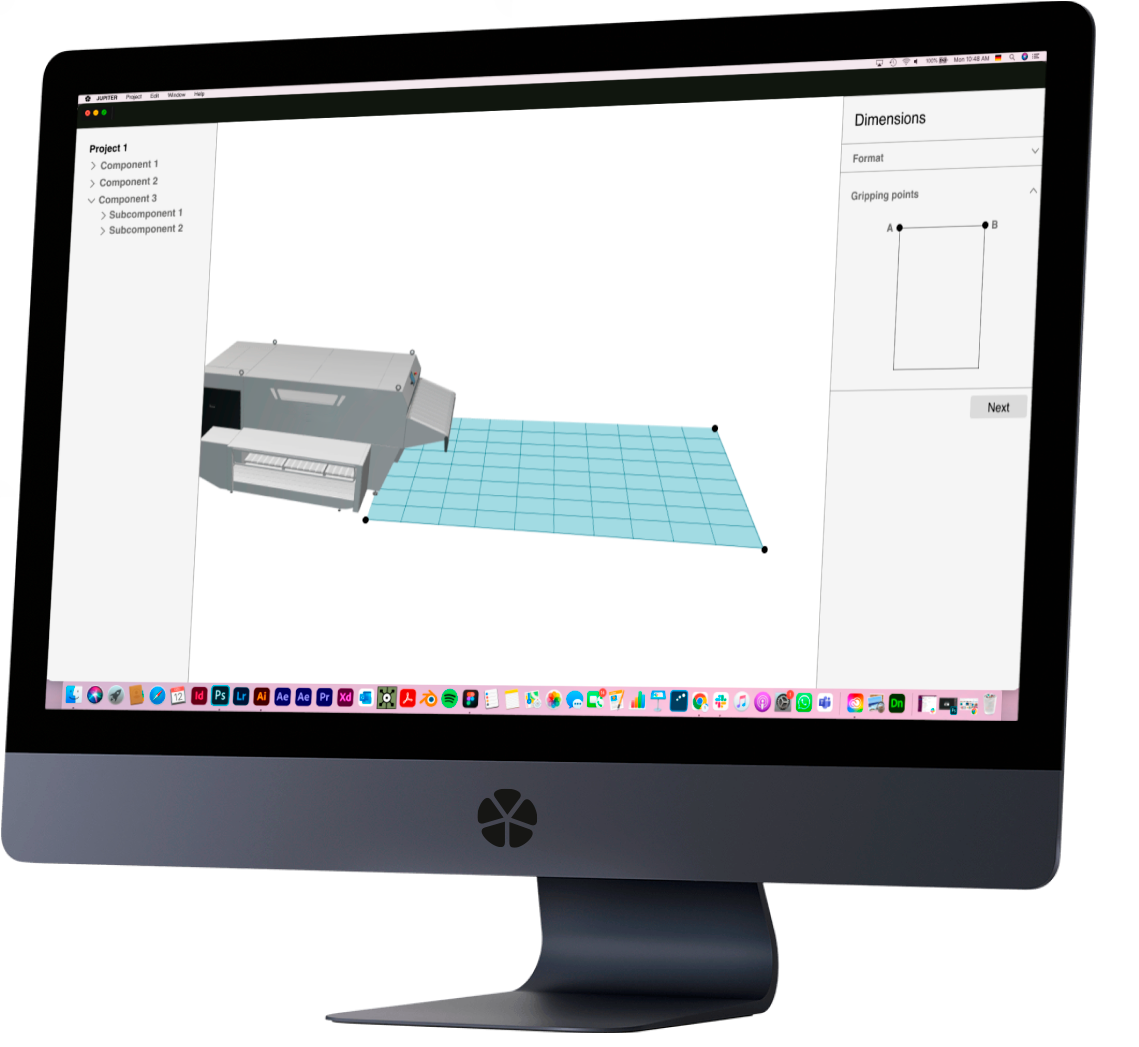

sewts.JUPITER will drastically change the way automation engineers work.

In the process of automating our specific use cases, we are developing all necessary software modules and hardware components to automate any process that involves easily deformable materials.

These tools will be combined in JUPITER, our one-stop-shop software suite for automation engineers. While robotics hardware is consistently getting cheaper, the development cost for new automation solutions is what actually keeps industries from driving automation forward. With sewts.JUPITER, we will be able to significantly reduce development times and cost for automation solutions that deal with deformable materials.

Here’s how it will work: In a simulation-based environment, automation engineers will be able to input all process parameters relevant to an industrial automation project and effortlessly receive the design for a fitting robot cell as well as the code for robot controls as well as the system logic.

By eliminating time-consuming preparatory work, engineers will have more time for tinkering and testing new ideas.