Company

Opening up new possibilities for automation technology.

Vision & Culture

Ready to become the global go-to partner for automation processes dealing with easily deformable materials.

Our technology can provide solutions to many industries. But our main vision that we strive to accomplish is to enable a complete and customized automation of clothing production. Our name is a wordplay on “to sew” and “suit” and it embodies this goal:

Enabling robots to sew a suitable suit!

Why is that our vision? We believe in sustainability and prosperity through automation. Processes involving the handling or production of textiles are often performed far away from the place where the textiles are actually being used, therefore requiring an enormous transportation effort. By automating these processes, we can move them back right to where they’re needed in a cost-efficent way. This way, we will shorten transportation routes, create more reliable supply chains, save CO2 emissions and tackle the issue of overproduction.

These are our core values we live by:

Freedom

Seeing your decisions evolve into accomplishments is truly inspiring. That’s why, we encourage the freedom to speak your mind, to be self-determined in the way you work and to develop the skill set you desire.

Team Spirit

To us team spirit means having confidence in the work we do as well as in the future of our projects. It means sharing a sense of belonging as well as spending time together.

Humor

Truly being yourself and leaving pretentiousness behind is driving our motivation to overcome every day challenges. We know that sharing a genuine laugh with the team helps us tackle every challenge. That is why humor is so important to us.

Openness

We know that working in a culture of openness multiplies your options for the future. We value openness towards new ideas and opinions as well as criticism and self-reflection. Every challenge you face today helps you become a better version of yourself tomorrow. Stay curious!

As a deep-tech company, we work according to the following principles:

- Perfect is the enemy of good enough.

- As simple as possible as complex as needed.

- KISS – Keep it simple, stupid!

- The best idea wins, no matter who it is from.

- Don’t fall in love with your feature or part.

- Product first, ego last.

- Great products are built by great teams, the foundation of which are awesome people.

sewts in Numbers:

Team

We want to put our team first

– in our daily work as well as on this website. We’re made up out of a group of driven, diverse and unique individuals, each bringing in their own perspective to be a part of something bigger.

Meet our Founders!

At the core of our team are our founders Alexander, Tim and Till. From a common background in mechanical engineering, they developed to be the three corner stones of our team, leading the Business Operations (Alex), Hardware Team (Tim) and Software Team (Till).

Making it all possible: Our Investors.

We could not do what we do without our investors. Not only because of funding, but because of the invaluable experience and knowledge they bring to the table. We’re extremely proud to work with High-Tech Gründerfonds, Bayern Kapital, APEX Ventures and Initiative for Industrial Innovators.

Sustainability

Automation is one of many puzzle pieces to combat climate change – we’re ready to do our part.

Automation and AI will transform our economies and our workplaces within the next years, having significant impact on all of our lifes. At sewts, we are developing innovative technology with the capacity to automate many processes that have never been automated before, so we are part of that transformation. While doing so, we want to make sure to that our impact on the world is positive.

Climate change is undoubtedly the biggest challenge of this century. Every individual can make an effort to limit their carbon footprint, but it is important to recognize that a lot of responsibility lies with government and large corporations. Automation is a one puzzle piece to make production processes more sustainable.

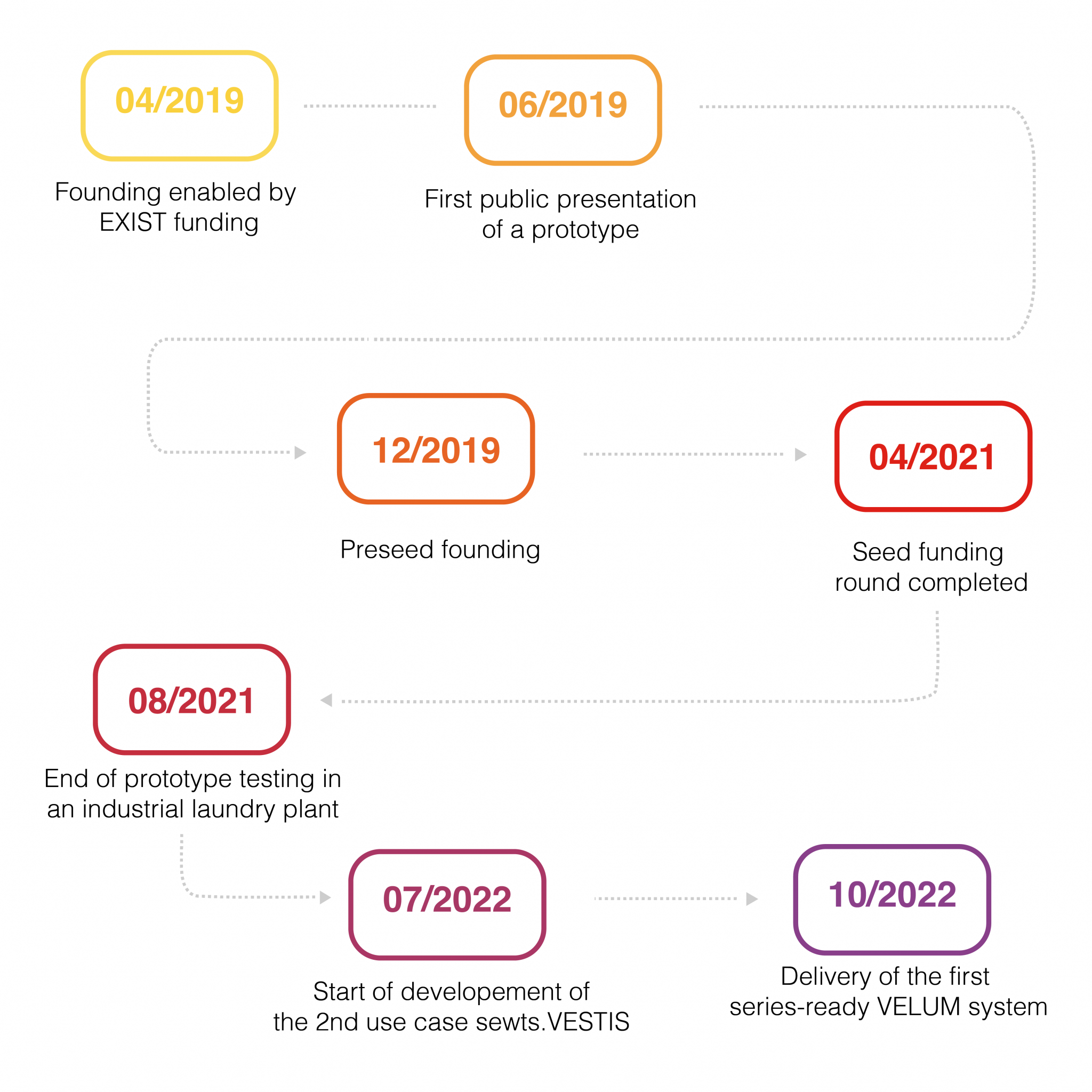

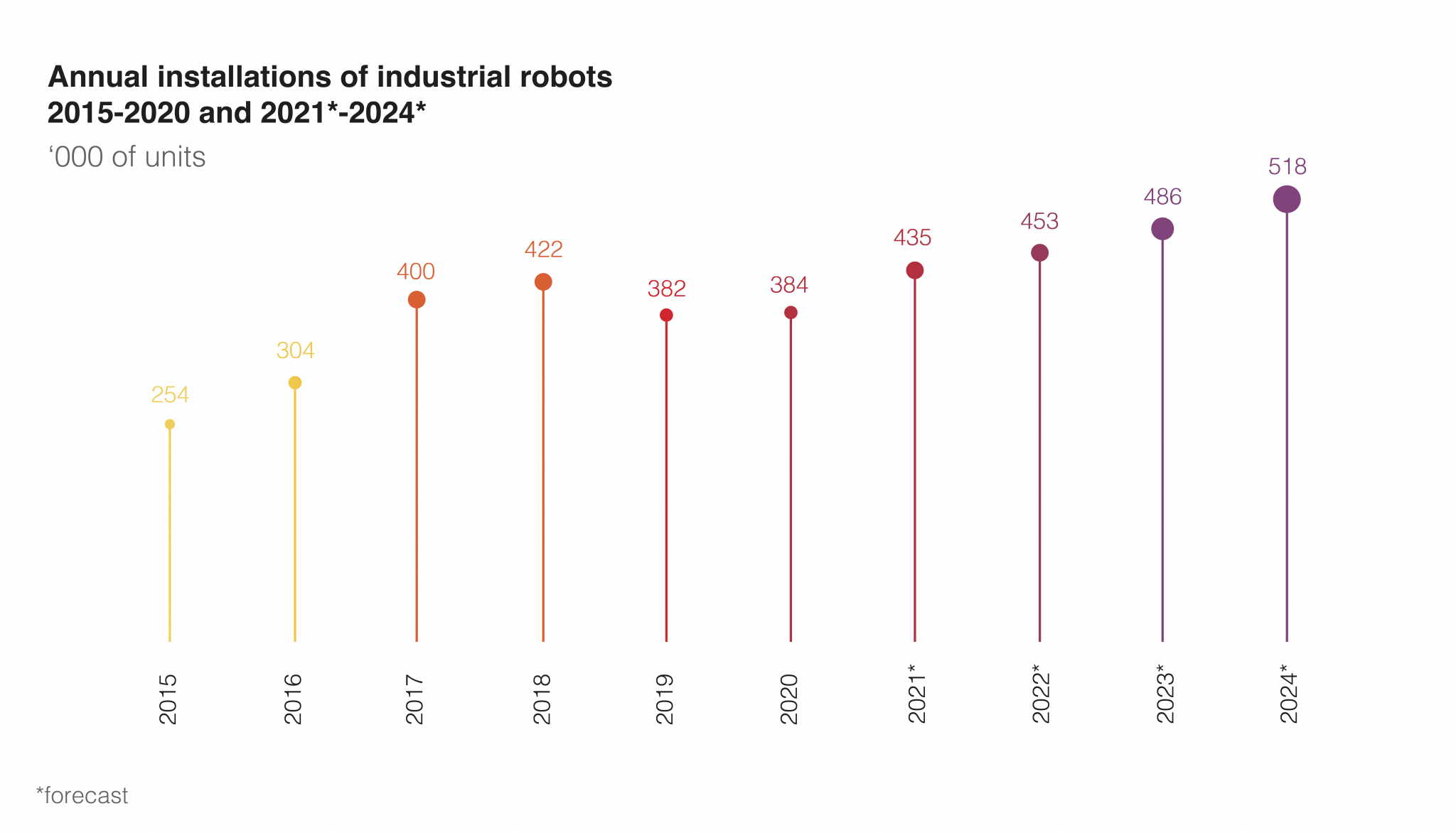

Source: World Robotics 2021

It is our goal to use automation of industrial processes to cut carbon emissions.

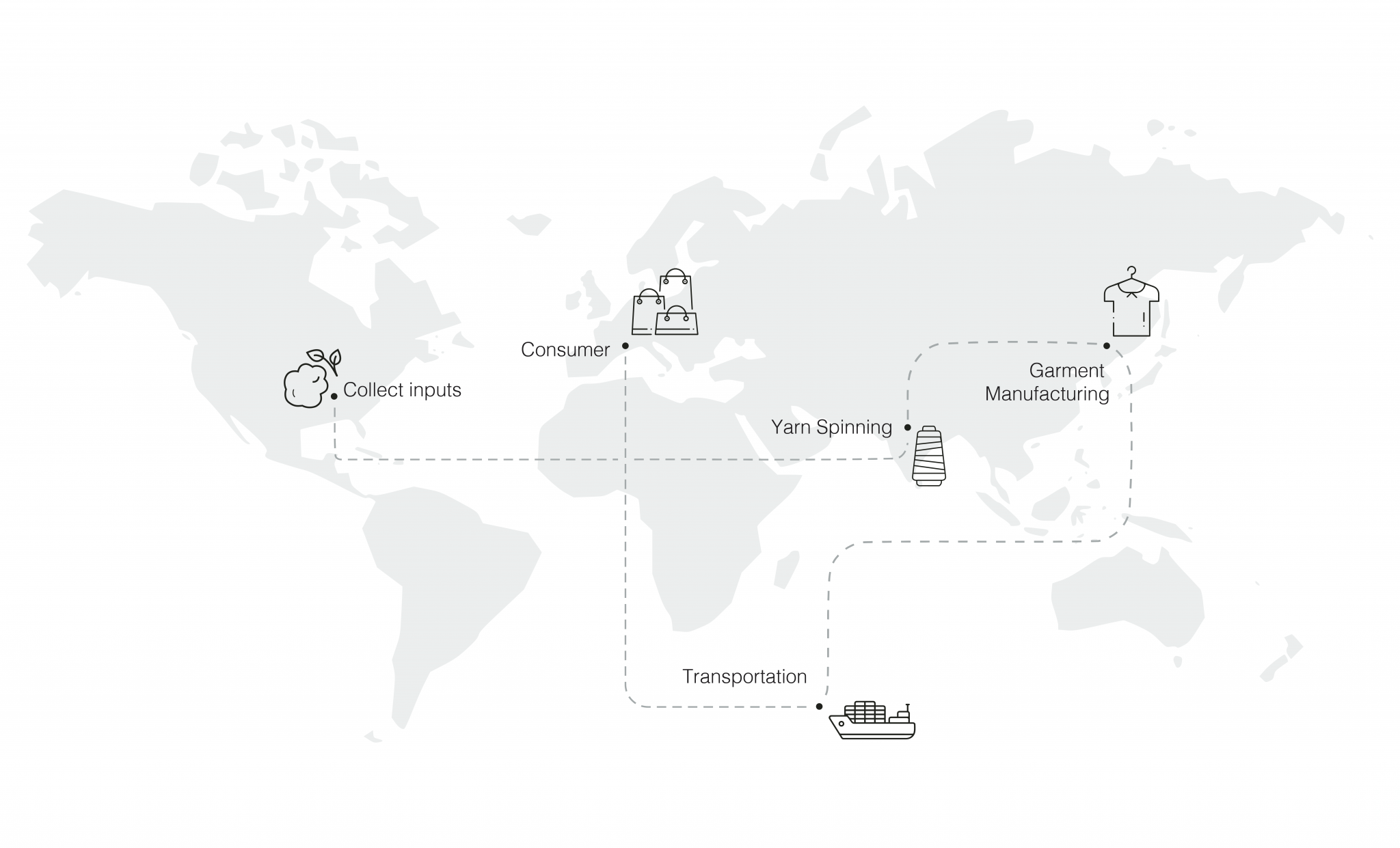

Let’s look at the garment industry specifically. According to a recent report from the World Resources institute, it emitted 1.025 gigatonnes (Gt) of carbon dioxide in 2019 and this number will keep growing if there are no counter-measures, as the industry in general is growing.

The production process usually involves multiple, resources-intensive steps with long transport routes in between. A fast fashion t-shirt is likely to have traveled between 20.000 and 65.000 kilometers before it reaches your local store. Additionally, it matters how it travels: Most likely via cargo ships, which are able to transport large amounts of goods, but are also extremely polluting on account of their use of heavy fuel oil .

Through automation, we want to significantly reduce emissions in the garment industry by bringing back local production – meaning that garments can be made in close proximity to where they’re needed – as well as limiting overproduction, since clothing can be made on demand, tailored to your body. This is possible because automation is cheaper than manual labour in big industrialized countries. The only thing missing so far is the robotic intelligence, which sewts is now providing.

The garment industry is a good example for the climate-saving impact of automation, but of course it’s the same for many other production processes. Think about other textiles, like carseat covers, rubber parts that need to be assembled as part of larger machines, or even the food industry. Automation prevents the use of cheap labour with the environmental price tag of shipping items across the globe.

¹ Source: Industrievereinigung Chemiefasern e.V.

² Source: Umweltbundesamt